Advantages Of Polyamide Thermal Break Over Resin Thermal Break

What's The Difference Between Polyamide & Resin Break

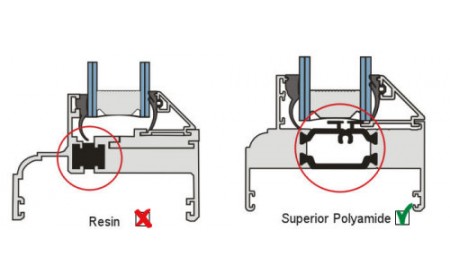

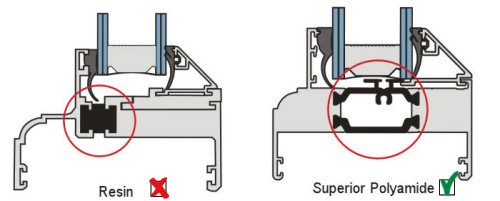

On the left is a technical drawing showing an old resin thermal break barrier on an old Premium fixed lite, next to and surpassed by the polyamide thermally broken profile. The old resin break windows are no longer in production here at Duration Windows. On the right you can see a technical drawing showing a superior polyamide thermal break barrier on a NEW Premium fixed lite. As you can see at a first glance it is a lot larger barrier and has an air gap in it that is similar to the thermal chambers in PVCu windows.

Our aluminium products are all designed for the future. All of our aluminium window and door systems have long since been upgraded to a superior polyamide thermally break barrier as opposed to the old Resin thermal break barrier still used in some window systems. The Polyamide gives at least a 30% improvement to all thermal efficiency and Uw figures on a typical window (1480 x 1230mm). It is these superior polyamide thermally broken aluminium profiles that have enabled us to produce an aluminium ‘A’ Rated window system known as our Premium Plus window system.

Advantages Of Polyamide Thermal Break Over Resin Thermal Break

- Meets the building regulations for NEW BUILD jobs ( now and in october 2010 when more stringent regulations come into force).

- Polyamide has a much improved thermal performance i.e. at least a 30% improvement in Uw figures on a typical window (1480 x 1230mm).

- Ability to have larger thermal barrier i.e. Polyamide strips of up to 30mm compared with 5/6mm PU resin thermal break.

- Dual colour options far easier and cheaper to achieve with polyamide i.e. individual sections can be painted before assembly.

- Increased flexibility (Hybrid Sections) - using Premium window sections can be used in a number of combinations.

- Polyamide has similar mechanical properties to aluminium i.e. assembled profiles retain their rigidity and have far greater strength.

- Has the same heat coefficient as aluminium (melting point, etc.) so it does not crack or distort when subject to extreme cold or heat.

- Resin gives off poisonous gases when it melts or ignites in the event of a fire.

- Polyamide is a fibreglass compound which means that it can bend without cracking, and can easily produce curved and arched windows. (Resin becomes weakend and tends to splinter under the tensile strain)

- Much reduced risk of condensation / fogged up sealed units.

>>>>>Note: Article sourced from DURATION WINDOWS<<<<<