What is the role of Polyamide Insulating Bars in Energy-Efficient Aluminium Windows?

Essentially, a polyamide insulating bar in an energy-efficient aluminium window frame creates a thermal break in the structure which can be used to meet the modern needs of building physics. When seeking a cost-effective solution for the improvement of thermal values of a structure, aluminium casement windows have long been considered as one of the best options, for example when compared to uPVC. Moreover, with the addition of polyamide insulating bars to create thermal breaks, their thermal insulation properties can be improved no end.

Polyamide is a material that can be a macromolecule or a polymer. Structurally, the material has large numbers of monomers which are linked together by bonds of amides – a group of chemical compounds. It is worth noting that a polyamide can occur both naturally as well as being artificially manufactured and that they are put to use in a wide variety of products in all sorts of applications.

For example, naturally occurring polyamides can be found in wool and silk as proteins. Instances of artificially manufactured polyamides include things like nylon and ABS, an engineering plastic.

Advantages of reinforcing aluminium window frames with polyamide bars

When a thermally insulated aluminium window frame is reinforced with polyamide bars, these components are actually inserted between the interior and exterior profiles of the product. They can be fitted to aluminium window frames as well as high-end aluminium doors and high-end aluminium façades during the manufacturing process and have huge benefits compared to similar products which lack them.

For example, a polyamide insulating bar inside a frame prevents the transfer of heat from either the inside to the outside or vice versa. This means they are ideal in both winter and summer, depending on the environmental conditions they face. In common with other insulation systems, they prevent the frames from feeling cold when it is icy outside as well as preventing heat loss from the inside to the outside. Equally, when it is hot outside, they help to prevent the interior of a structure from warming up excessively.

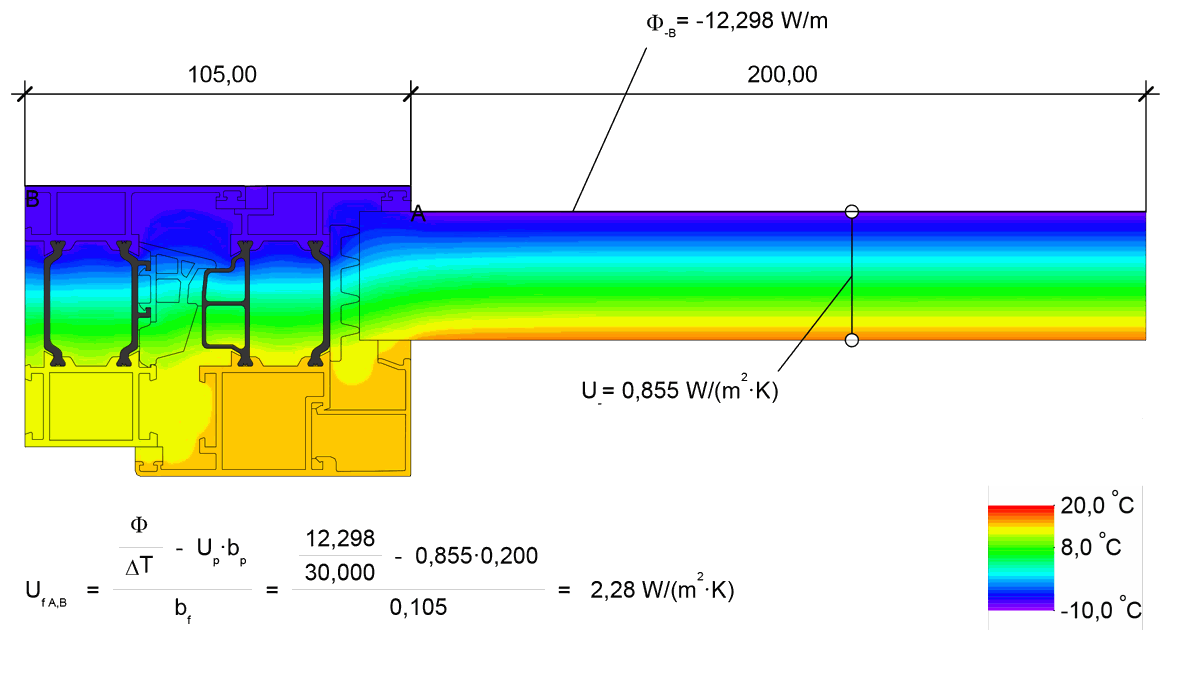

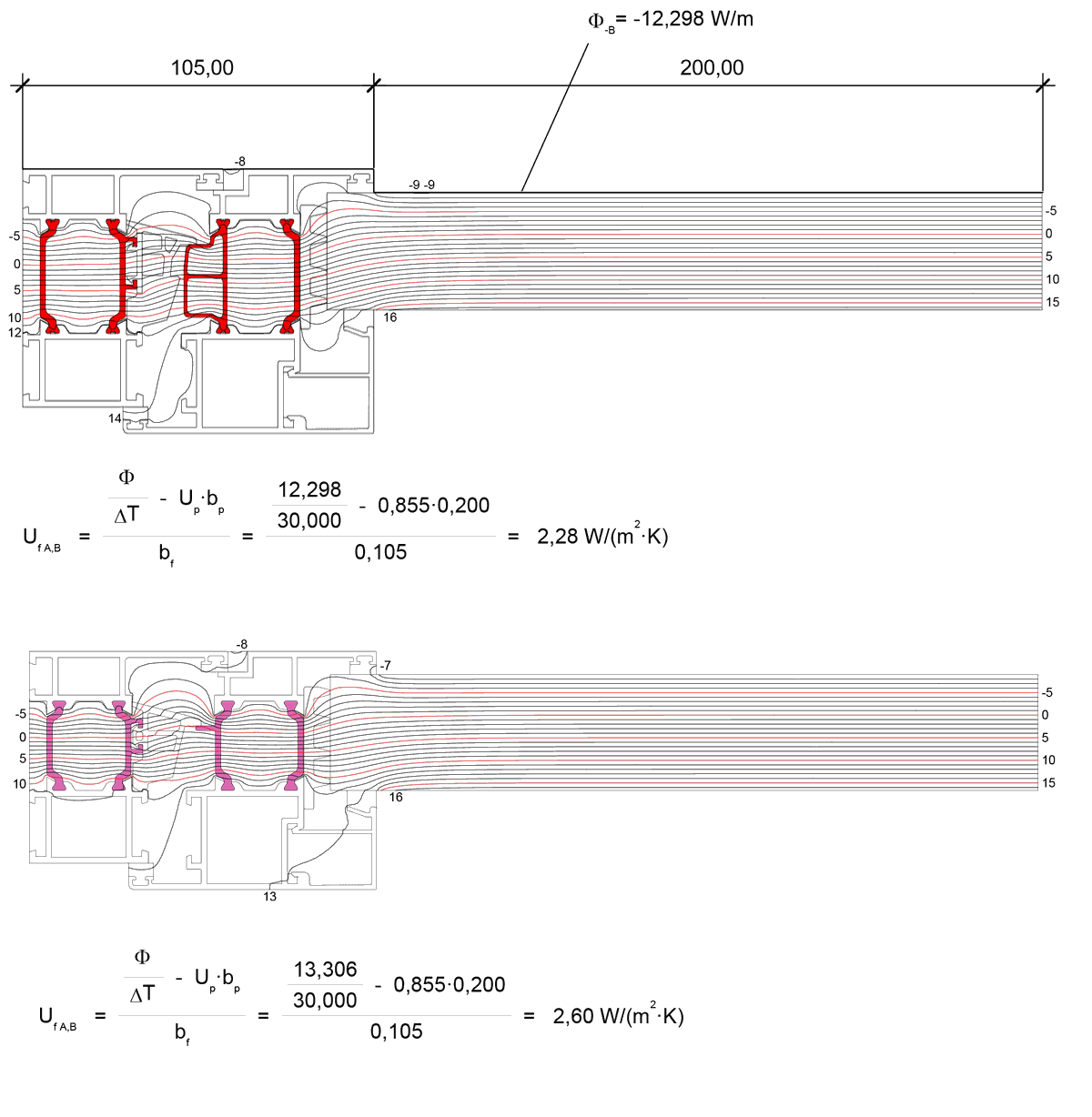

Improving Uf values with polyamide bars

When used with thermally efficient glazing, polyamide bars in the frames of aluminium windows will provide better Uf values. Where the commonly expressed U value of a window relates to the thermal insulation rating of its glazing, usually given in Watts per m2K, the Uf rating also includes the rating of the frame. For building designers who are seeking an overall building physics that is as thermally insulated as possible, then measuring the windows by their Uf rating - not just the glazing element - makes a great deal of sense. However, that is not all. The addition polyamide insertions also reduces noise from being transmitted into a building from the exterior, thanks to the break they create inside.

"A high-performance window must have low heat loss and air leakage, but high solar transmission."

Anne-Grete Hestnes et al in their book Solar Energy Houses: Strategies, Technologies, Examples

The low profiles of aluminium frames are often excellent at allowing light to flood in as well as preventing unwanted airflow, but without polyamide bars are not so strong with thermal retention. Compared to some other frame materials commonly used, such as timber, aluminium alone can produce inferior results with thermal transmittance. It is only the addition of a thermal break consisting of a material of low thermal conductivity that will guarantee performance to be strong.

To achieve this, it is necessary to make the gap between the front and the rear of an aluminium frame as large as possible while the break between the frame and the polyamide bar inside should be kept as minimal as is feasible, according to Hugo S. L. Hens. As such, a high degree of engineering expertise is required to achieve optimal results from thermally separated glazing products of this type, something that all building designers and buyers should bear in mind when selecting a manufacturer.

To achieve this, it is necessary to make the gap between the front and the rear of an aluminium frame as large as possible while the break between the frame and the polyamide bar inside should be kept as minimal as is feasible, according to Hugo S. L. Hens. As such, a high degree of engineering expertise is required to achieve optimal results from thermally separated glazing products of this type, something that all building designers and buyers should bear in mind when selecting a manufacturer.