LABORATORIES

We have our own laboratory for common testing items, and two cooperated labs for regularly authoritative inspection. All extruded plastic profiles are in line with the Chinese standard 2017 version and the European Standard, further more our KAXITE series polyamide thermal insulation strips support OEM for performance.

Due to the great progress and high performance, we were invited as the earliest member of the Chinese National Standard Committee, after years of development, we became the leader of the Chinese National Standard Committee (for revising of GB/T 23615.1-2017).

For the constructional plastic profiles, we do the production and experiment in accordance with the standards below:

|

Authoritative Test |

Dimension Test |

Ash Test |

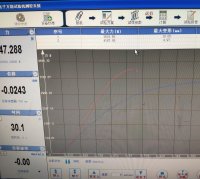

Mechanical Performance |

-30℃ Weatherability |

Apart from the shapes of polyamide thermal break which can be tested directly, the custoimzed special shapes can't be tested directly, so we take specimen from the polyamide profiles and do the testing.

|

Specimen Design |

CNC Machining |

Specimens Off |

Testing |

Datas Out |

Actually, the Chinese standard GB/T 23615.1-2017 has more testing items than the European standard. Further more, we can realize extremely high performance values for customers. According to all of these, we can do the experiment items like below:

performance table of PA66 GF25 Building material -- heat insulation strip

1. Sample water content less than 0.2% by weight.

No.

Characteristic

Size of Thermal

Break

GB/T

23615.1-2017

KAXITE

Customize

1

Density

(1.30±0.05)g/cm3

1.25~1.45

2

DSC melting peak temperature

≥255℃

≥255℃

3

Stress cracking by shaft nail

No crack at orifice

No crack at orifice

4

Shao hardness HD

80±5

80±10

5

Low temperature notched impact strength(-30℃±2℃)

≥50kJ/m2

≥50kJ/m2

6

Room temperature longitudinal tensile eigenvalue(23℃±2℃)

≥90MPa

≥100MPa

7

Room temperature longitudinal tensile elongation

≥3%

≥3%

8

Room temperature longitudinal tensile modulus of elasticity

≥4500MPa

≥5500MPa

9

Transverse

tensile eigenvalue

in room temperature (23℃±2℃)

I type(Width<20mm)

≥90MPa

30~140MPa

10

I type(Width≥20mm)

≥80MPa

11

special shape

≥25MPa

12

Transverse

tensile eigenvalue

in high temperature(90℃±2℃)

I type(Width<20mm)

≥55MPa

13

I type(Width≥20mm)

≥45MPa

14

special shape

≥20MPa

15

Transverse

tensile eigenvalue

in low temperature(-30℃±2℃)

I type(Width<20mm)

≥90MPa

16

I type(Width≥20mm)

≥80MPa

17

special shape

≥25MPa

18

Transverse

tensile eigenvalue

(Hydrolytic resistance, boiling for 4h or keep in 23℃ water for 1000h)

I type(Width<20mm)

≥85MPa

19

I type(Width≥20mm)

≥75MPa

20

special shape

≥22MPa

21

Transverse

tensile eigenvalue

(Thermal aging properties, 140℃ for 1000h)

I type(Width<20mm)

≥60MPa

22

I type(Width≥20mm)

≥55MPa

23

special shape

≥20MPa

24

Typical value of

thermal conductivity

Heat flow metering

method

0.30W/(m·K)

0.30W/(m·K)

25

Linear coefficient of

expansion

2.3×10-5K-1~3.5×10-5K-1

2.3×10-5K-1~3.5×10-5K-1

26

Fiberglass Content

-

0~70%

27

FLAMMABILITY (UL94)

-

94V-0

2 Normal laboratory condition:23℃±2℃ and 50%土10% relative humidity.