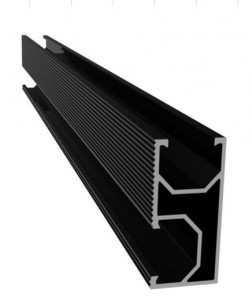

Solar Panel Mounting PA66 GF45 Replace Aluminum Rail For Solar Energy System

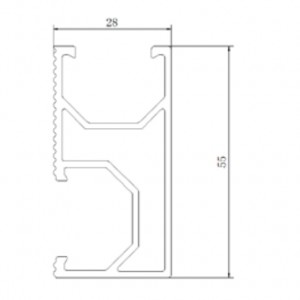

System features and specifications:

- Dimensions: 4200 x 55 x 28 mm

- Suitable for pitched and flat roofs and solar photovoltaic panel mounting

- Cladding type: tiled, slate and sheet metal (other roof mounts also available)

- Maximum slope: 60 degrees

- Maximum building height: 20m

- Wind Load: up to 60m/s

- Snow Load: up to 1.4KN/2

- Module width: any

- Module thickness: up to 46mm

- Material: PA66 GF45

- Color: black

- SGS/TUV/SUD/CNAS/ISO9001:2008 Certification

- Warranty: 20 years durability on material

- Manufacturer: Jiangyin Kaxite Technology Co., Ltd

Solar Panel Mounting PA66 GF45 Replace Aluminum Rail For Solar Energy System

The mounting rails are the core of the system. For each row of panels, a pair of rails is mounted horizontally on the roof and supported by rook hooks at no more than 1.2m intervals. The panels are then laid on the rails and clamped in place with black end clamps and black mid clamps to match.

For long rows, simply join lengths of rail using the rail splice kits. Rails can be cut to length with a hacksaw or grinder. Alternatively we can cut them to the length that you require.

System features and specifications:

- Dimensions: 4200 x 55 x 28 mm

- Suitable for pitched and flat roofs and solar photovoltaic panel mounting

- Cladding type: tiled, slate and sheet metal (other roof mounts also available)

- Maximum slope: 60 degrees

- Maximum building height: 20m

- Wind Load: up to 60m/s

- Snow Load: up to 1.4KN/2

- Module width: any

- Module thickness: up to 46mm

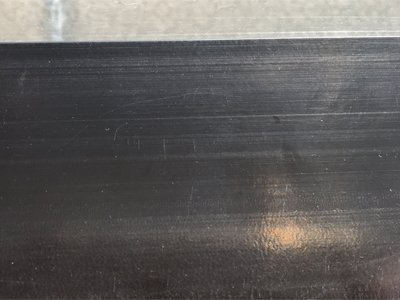

- Material: PA66 GF45

- Color: black

- SGS/TUV/SUD/CNAS/ISO9001:2008 Certification

- Warranty: 20 years durability on material

- Manufacturer: Jiangyin Kaxite Technology Co., Ltd

Compare with Aluminum

|

PERFORMANCE |

POLYAMIDE MOUNTINGS |

ALUMINIUM MOUNTINGS |

|

Density - g/cm3 |

1.35±0.05 |

2.70±0.1 |

|

Conductivity |

No |

Yes |

|

Oxidation resistance |

Yes |

No |

|

Corrosion resistance |

Yes |

No |

|

Life - Years |

50 |

30 |

|

Cost |

Lower |

High |

|

Production process |

Extrusion |

Extrusion |

-

Density of polyamide is only 1.35 g/cm3, half of the density of aluminum, lighter and lower cost.

-

Aluminum is a kind of highly activing metal, suffered from the corrosion from the environment. Polyamide is a kind of plastic which has excellent property of corrosion resistance, so has longer life than aluminum.

Polyamide (PA66GF) 13 years exposed to the environment, no corrosion happen.

Aluminium profile 13 years exposed to the environment, oxidation reaction, acid corrosion reaction happened.

-

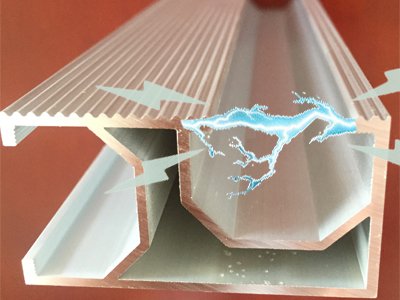

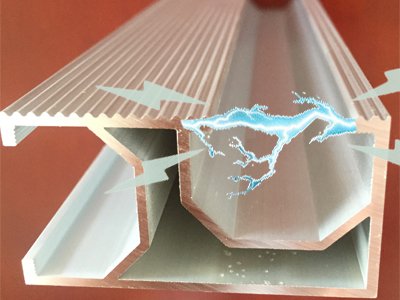

Most components applicated in electric systems are insulated, due to the limitation of technology and objective actors, aluminium frames were used in solar power systems, to protect the solar photovaltaic chips. But the electrical conductivity causes the electricity leakage.

Polyamide is electrically insulated material, no leakage, more safe.

Aluminum causes the discharge and leakage of electricity.

-

90% Recyclable after 20 years!

- Density of polyamide is only 1.35 g/cm3, half of the density of aluminum, lighter and lower cost.

- Aluminum is a kind of highly activing metal, suffered from the corrosion from the environment. Polyamide is a kind of plastic which has excellent property of corrosion resistance, so has longer life than aluminum.

- Most components applicated in electric systems are insulated, due to the limitation of technology and objective actors, aluminium frames were used in solar power systems, to protect the solar photovaltaic chips. But the electrical conductivity causes the electricity leakage.

- 90% Recyclable after 20 years!