Why the IC-type thermal break strips appearing?

As the main material of the aluminum alloy heat insulation broken bridge doors and windows—insulation broken bridge aluminum profiles have a good heat conduction performance.

In order to insulate and heat insulation, the domestic introduction of the“thermal insulation broken bridge” technology to produce a “thermal insulation broken bridge "Aluminum profile", in the middle of the two aluminum profiles by adding a low thermal conductivity of non-metallic separators, can get excellent insulation properties of aluminum insulation, called "insulation broken bridge aluminum profiles." Advantages of heat-insulating bridge doors and windows: The heat-insulating bridge doors and windows have high strength and aging resistance. It can also be remanufactured, reused, recycled, reprocessed, and not wasted. The state clearly pointed out that the selection of doors and windows should consider energy saving and strength in the first place. Based on this, aluminum insulation profiles, with their superior performance, have pointed out the direction for the development of aluminum profiles in China. In order to avoid the insufficiency of the aluminum itself, a heat-insulating aluminum profile was developed. The principle of the aluminum heat-insulation is to penetrate the aluminum insulation bar and break the aluminum profile to form a broken bridge, which creates a block inside and outside the house. The barrier of hot and cold exchange effectively prevents the conduction of heat. It not only retains the advantages of aluminium profiles, but also greatly reduces the heat transfer coefficient of aluminum profiles (the entry "heat transfer coefficient" is provided by the Encyclopedia of the industry), and the energy saving effect is relatively good is the best choice for energy saving doors and windows. Isolation strips used for heat-insulating bridge aluminium profiles - is a polyamide nylon with reinforced glass fiber, a non-metallic separator with a very low thermal conductivity, so it has a good thermal insulation performance, in the same heat supply Under the circumstances, the use of heat-insulated bridge doors and windows than the ordinary doors and windows of the indoor temperature increased by 5 degrees Celsius or more, can be called a new energy-saving doors and windows.

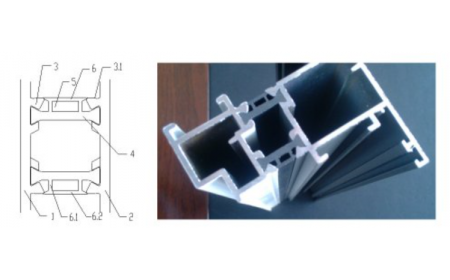

There are two main production methods for heat-insulating profiles (insert “insulation profiles” provided by the Encyclopedia of Industry): one is the use of heat-insulating strip materials and aluminium profiles, which are formed through mechanical teething, threading, rolling and other processes. “Insulation bridge” is called “insulation type” of heat insulation profile; the other is to pour insulation material into the insulation cavity of aluminum alloy profile, and after solidification, remove the broken bridge metal and other processes to form “insulated bridge”. "," called "casting" thermal insulation profiles. The inside and outside surfaces of the heat insulation profile can be profiles of different sections (words “section” is provided by the Industry Encyclopedia), or different color profiles of different surface treatments (words “surface treatment” provided by the Industry Encyclopedia). Due to geographical and climatic influences, there is a large gap between the coefficient of linear expansion of heat-insulating materials and aluminium profiles, and there is a large stress and gap between the two during thermal expansion and contraction; at the same time, heat insulation materials and aluminium profiles are combined. One, on the doors and windows, is equally as strong as aluminium. Therefore, it is required that the heat insulation material must also have the tensile strength, bending strength, expansion coefficient and elastic modulus close to the aluminium alloy profile, otherwise the heat-insulating bridge may be broken and destroyed.

In the development of doors and windows, the birth of aluminium doors and windows allows people to broaden their horizons. The most energy-saving part the insulation bar in windows with insulation profiles are classified into the following types: I-type bars, C-type bars, O-bars, H-bars, T-bars, and so on. The GB/T 23615.1-2009 national standards are divided into two types: solid bars (I-type bars)and hollow strips (special strips).

The most commonly used I-type heat insulation strip on the market now can guarantee a certain strength, but it is not in the same horizontal plane as the outer edge of the card slot, so there is a phenomenon of accumulation of water and dust. And its use of features is not enough, and later improved the I-type insulation bar, resulting in a variety of special-shaped bars, such as the appearance of C-type bar to solve the phenomenon of dust, but the strength is far less than the I-type bar, and then was born O Strips, H-bars, T-bars, and so on. The evolution and development of these types of insulation bars meet the needs of various functions. Compared with the prior art, the prior art has integrated heat insulation strips used in the market, lack of design and use safety, and thus Kaxite Company has designed, developed and produced a new type of thermal insulation strip to make up for the shortcomings of the previous thermal insulation strip—IC type. Insulation bar! The birth of the IC-type thermal insulation strip not only achieved the strength of the I-type strip, but also exceeded the structural function of the C-type strip, making the thermal insulation strip no longer accumulate dust and water, no longer deformed, and enhanced The thermal conductivity of the hot profile, which is also very beautiful in appearance, is a product with relatively high applicability.