Simple detection method of heat insulation strip

Here we introduce several simple and quick detection methods:Appearance、Torsion breaking test、ordinary lighting experiments、rapid high-temperature calcination method.

Simple detection method of heat insulation strip

According to the standards in GB/T 23615.1-2009 standards to assess the quality of heat insulation bars; through the detection of some key performance indicators to assess the quality of insulation products (such as factory inspection items); through a simple and quick method to qualitative assessment Thermal insulation quality. However, due to qualitative inspection methods, most of the inspection items are relatively limited, so we can also pass third-party verification, in accordance with the full set of authoritative inspections; refer to GB/T 23615.1-2009 provisions for some key tests. Secondly, we can also inspect the supplier's production base, visit the workshop production process, and understand the company's management system. Here we introduce several simple and quick detection methods.

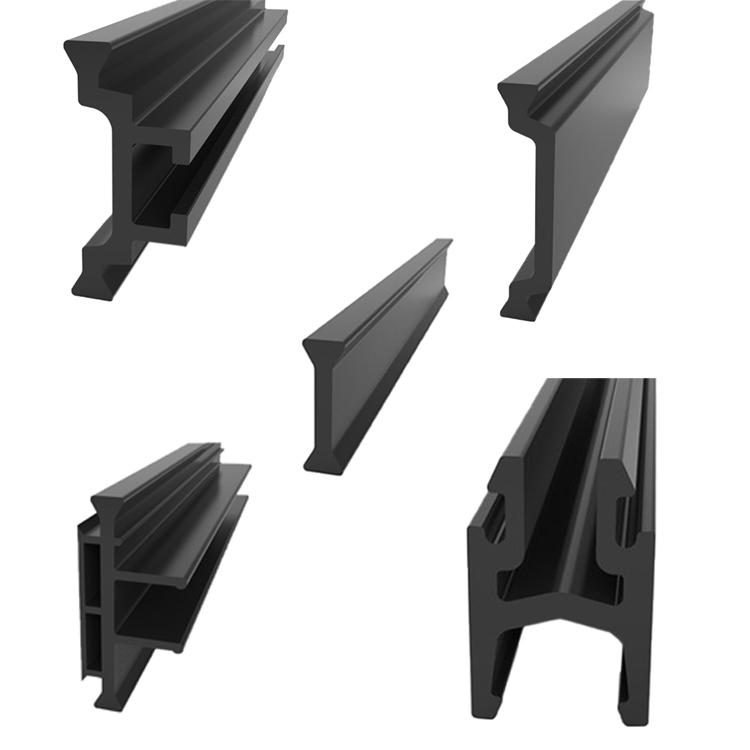

1. Appearance: PA66 nylon heat insulation strip has black matt color on the surface, and the whole is smooth and smooth, no shrinkage hole, no looseness, no scratches and die extrusion marks, and the special gloss of glass fiber can be seen through the light. There is no parting line mark on the end face of the hot stripe head, and more importantly, there is no resistance line in the heat insulation stripe. The most critical reason for the generation of resistance lines is that the technology of molds is not pure and the insulation material itself is not pure. Therefore, the strips are uneven and have some trouble for production. Therefore, some imperfect manufacturers change the manufacturing process. The resistance line is insufficient to make up for, and the open tooth of profile does not match with the resistance line completely. As a result, the resistance line will affect the contact surface of the profile. Therefore, the shear force (the term “shear force” is provided by the industry encyclopedia) has a great influence. .

2. Torsion breaking test: take a 25 cm sample of the type I strip for human breaking test. If the thermal insulation strip is bent to a certain distance between both ends, it will produce multiple segments of cracking (glass). “Provided by the Encyclopedia of Industry” caused by non-uniform fiber particles), or toughness (word “toughness” provided by the Encyclopedia of Industry) is obvious, repeatedly repeated bending (insufficient glass fiber content, not pure PA66); there are The T-bar, which is actually used and needs to reach a certain strength, is the middle part of the T-bar. We can use the two ends of the model heat-insulated bar to apply force in the forward and backward directions, and carry out a 360° rotation test. The low-end thermal insulation strips will be broken and broken. On the contrary, the good-quality thermal insulation strips have sufficient strength and toughness, and the torsional resistance is strong, and the state of the T-bars remains unchanged.

3, ordinary lighting experiments: good nylon insulation strip is not easy to light and a pale yellow flame, with a faint aroma. On the contrary, other so-called heat-insulated bars glow blue flames and emit a large number of pungent black odor smoke.

4, rapid high-temperature calcination method: As the saying goes gold is not afraid of fire, because each product quality is good or bad depends on its raw materials. Take a section of about 10 centimeters on the iron sheet and burn it underneath. If it is burned, it will still maintain the shape of the heat insulation strip. After the heat insulation strips produced from other raw materials, it cannot withstand the high temperature and burn. The time is not only short but not Forming.