Solar Panel Tile Roof Mounting Frame Rail For PV Project

Detailed Information:

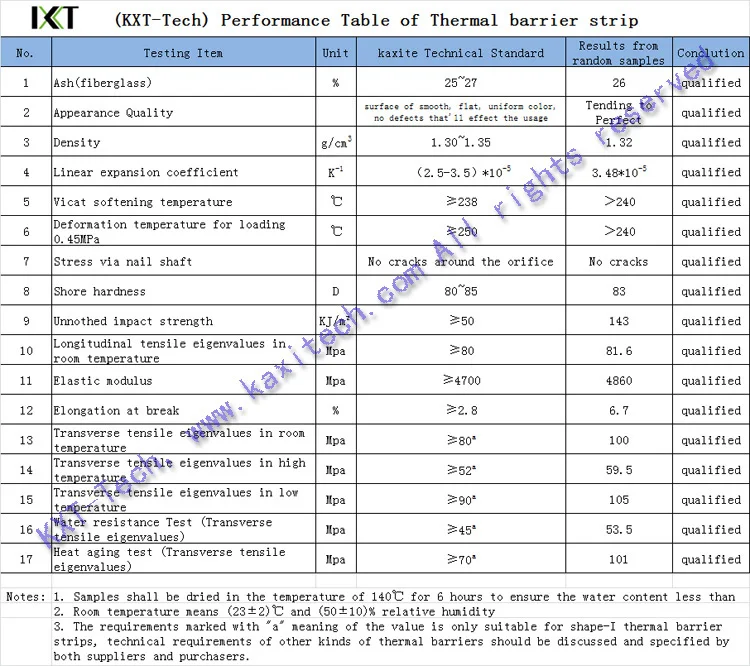

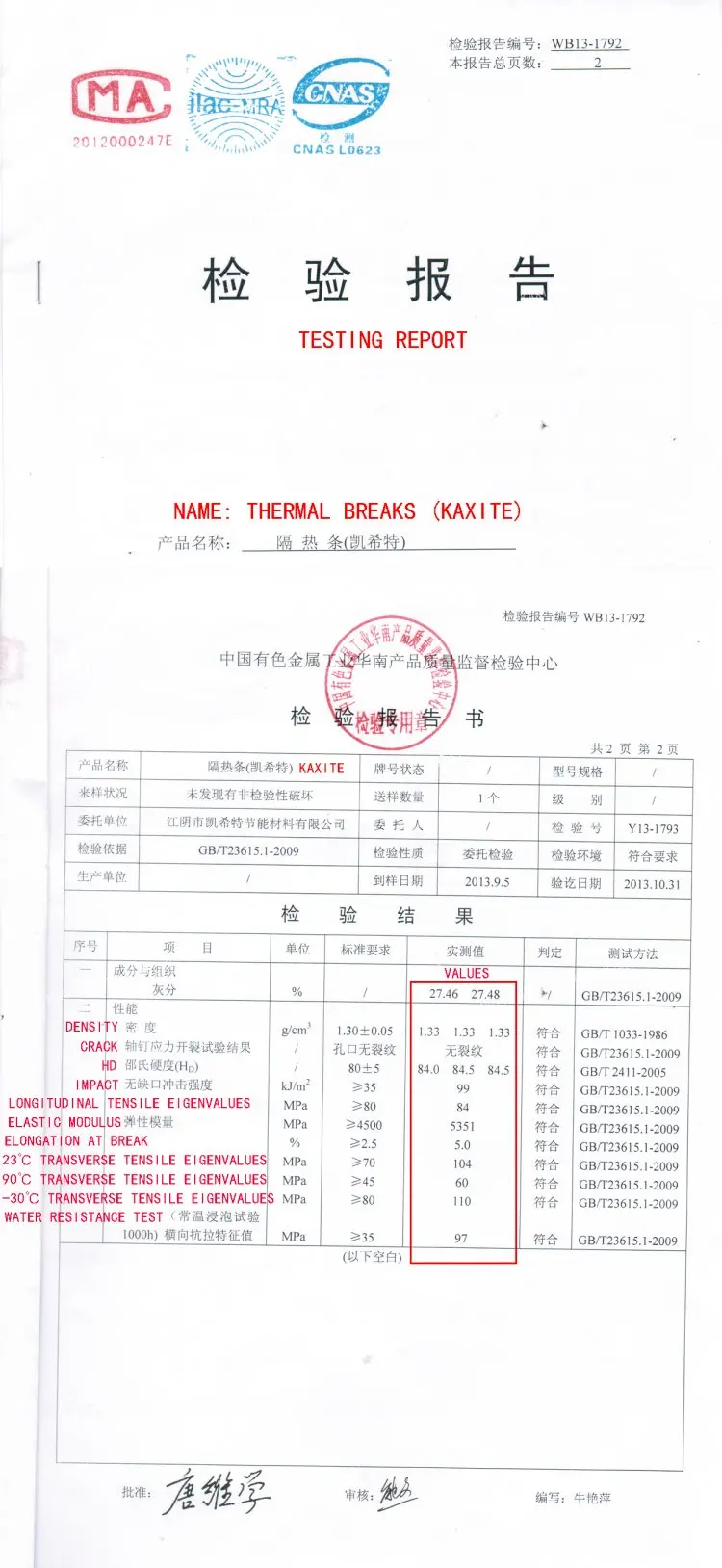

The performance of polyamide profiles are in line with the Chinese standard GB/T 23615.1-2009 and the European Standard EN 14024:2004, for KAXITE series, the performance is rather higher than the standard value.

Details of related standard:

- GB/T 23615.1-2009 Accessorial material for architectural aluminum alloy profiles -- Part 1: Thermal barrier strip of polyamide

- EN 14024-2004 Metal profiles with thermal barrier -- Mechanical performance Requirement, proof and tests for assessment

- YS/T 437-2008 Aluminium profiles moment of inertia calculation methods and computing software requirements

- JG/T 174-2005 Thermal barrier strips for construction industry

- GB 5237.6 -2012 Wrought aluminium alloy extruded profiles for architecture -- Part 6: Thermal barrier profiles

- GB/T 8478-2008 Aluminium windows and doors

- GB/T 8484-2008 Graduation and test for thermal insulating properties of doors and windows

- JG 175-2011 Insulating aluminum alloy profiles with thermal barrier for buildings

- UL94 Standard for Tests for Flammability of Plastic Materials for Parts in Devices and Appliances

- ASTM E84 Standard Test Method for Surface Burning Characteristics of Building Materials

- NFPA 285 Standard Fire Test Method for Evaluation of Fire Propagation Characteristics of Exterior Non-Load-Bearing Wall Assemblies Containing Combustible Components

In 2015, we became the leader of the Chinese National Standard Committee (for revising of GB/T 23615.1-2009) .

What's the most important component in the raw material of polyamide profiles for solar photovoltaic systems? Not Dupond, not extremely expensive fiberglass, it's Anti-aging agent and Antioxidants.

Good packaging, take care of what you care about!

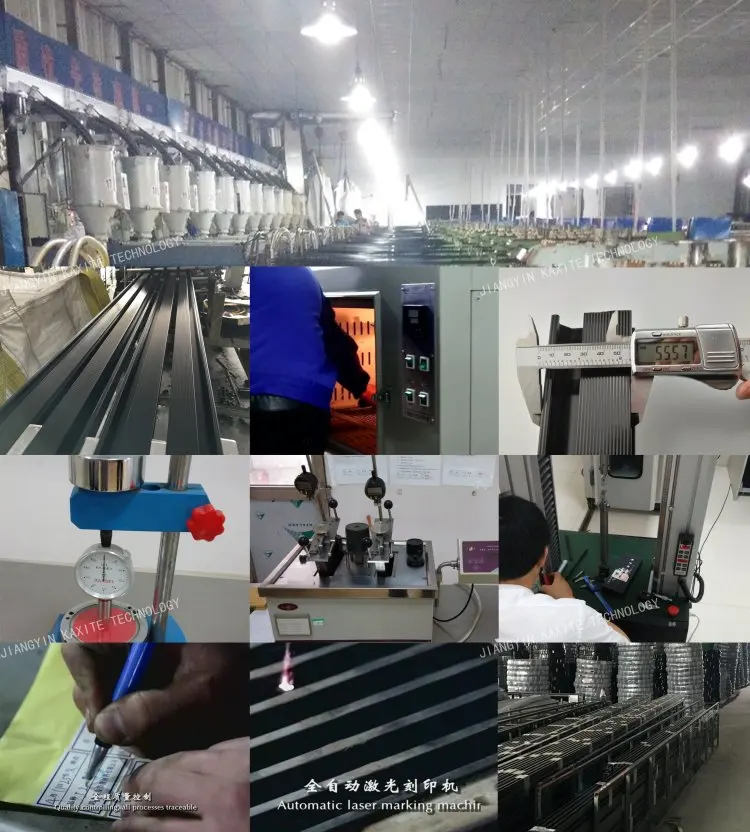

OEM of Performance (Granulation)!

Mostly we could finish the development of new products in 15 days.

The hardest thing is not thinking, but realizing. Most customers were upset that nobody could develop the shapes that they designed, some counterparts even came and looking for help to our workshop. We developing and cutting new dies for our customer, of course we never failed to develop any shape for our customers.

Service Advantages:

1, the design and development of new polyamide profiles, for any kinds of shapes you need for the polyamide profiles for solar photovoltaic systems, we can develop mould in a short time and send you the samples, actually we’ve successfully solved so much headaches for our customers and received satisfaction;

2, we offer the most advanced laser marking machine for custmers if a special mark on the polyamide profiles for solar photovoltaic systems is needed;

3, Here we offers most sizes from 10mm width to 1000mm or even bigger polyamide profiles for solar photovoltaic systems, which’s your best favor?

4, We provide matching equipment of PA66 polyamide profiles for solar photovoltaic systems for customers for the corresponding service followed.

An energy-saving Materials Technology Company.

ABOUT KAXITE® TECHNOLOGY

Jiangyin Kaxite Energy-saving Materials Technology Co., Ltd (abb.: KAXITE TECHNOLOGY, KXT-TECH) was originally a family business, developing since 2001, now acting as a group, who has her own two divisions, Plastics Extrusion Division, Non-woven Division, and some high-tech cooperation projects, which supported by Nanjing University Of Science and Technology, Jiangyin Technology Bureau, Guangdong Nonferrous Metal Research Institute...

It is developing so fast and there're more than 150 employees in the group, with 2 factories, 3 offices, and 1 cooperated factory, 2 cooperated laboratories, all are located in China.

Question: Do you have MOQ requirement?

Re: No, but the extra cost for package and logistic will be charged.

Question: Can we ask for samples?

Re: Yes, samples., will be free but express fee will be charged. Only 1 day needed for making samples ready.

Question: Can we customize special shapes of polyamide profiles? How many days cost?

Re: Yes of course you can, we support cutting dies for our clients. Mostly from 15 days to 30 days. We ensure 100% successful.

Question: Can we customize package styles, such as linear 5.8 meters?

Re: Yes.

Question: Can we customize marks on polyamide profiles?

Re: Yes.

Question: Why your price is higher/lower than others?

Re: We have our own capacity of granulation, to ensure the quality of polyamide profiles applicated in solar power systems, please kindly be noted that you will get the best products from us under the same price in the market.