PA66GF25 Fiberglass Reinforced Polyamide 6.6

PA66GF25 Fiberglass Reinforced Polyamide 6.6

Detailed Information:

We have our own capacity of granulation for Fiberglass Reinforced Polyamide 6.6 (PA66GF25,PA66GF30,etc..) and many other kinds of plastic granules. We're the only one who used the technology of Vacuum Drying for the polyamide, which could highly improve the natural performance of the nylon granules. Now the granulation capacity is near to 10.000 tons per year.

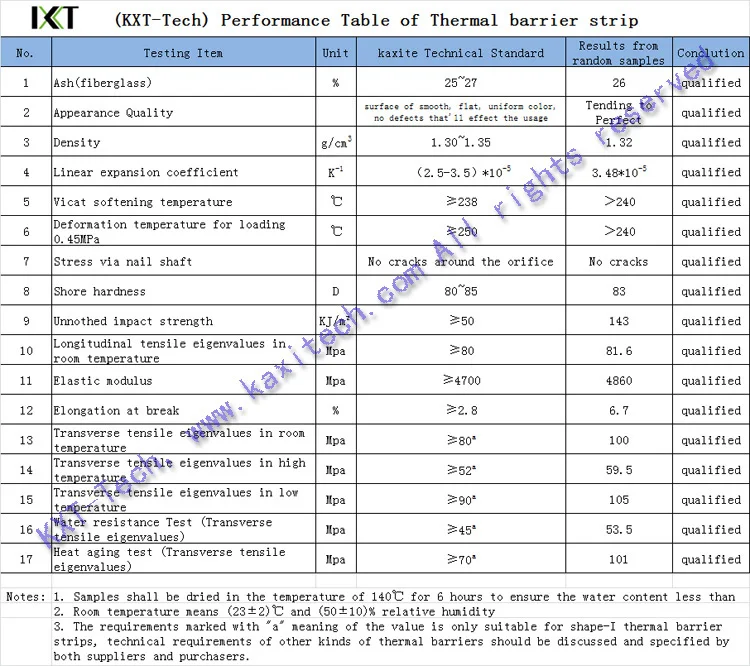

Technical Performance:

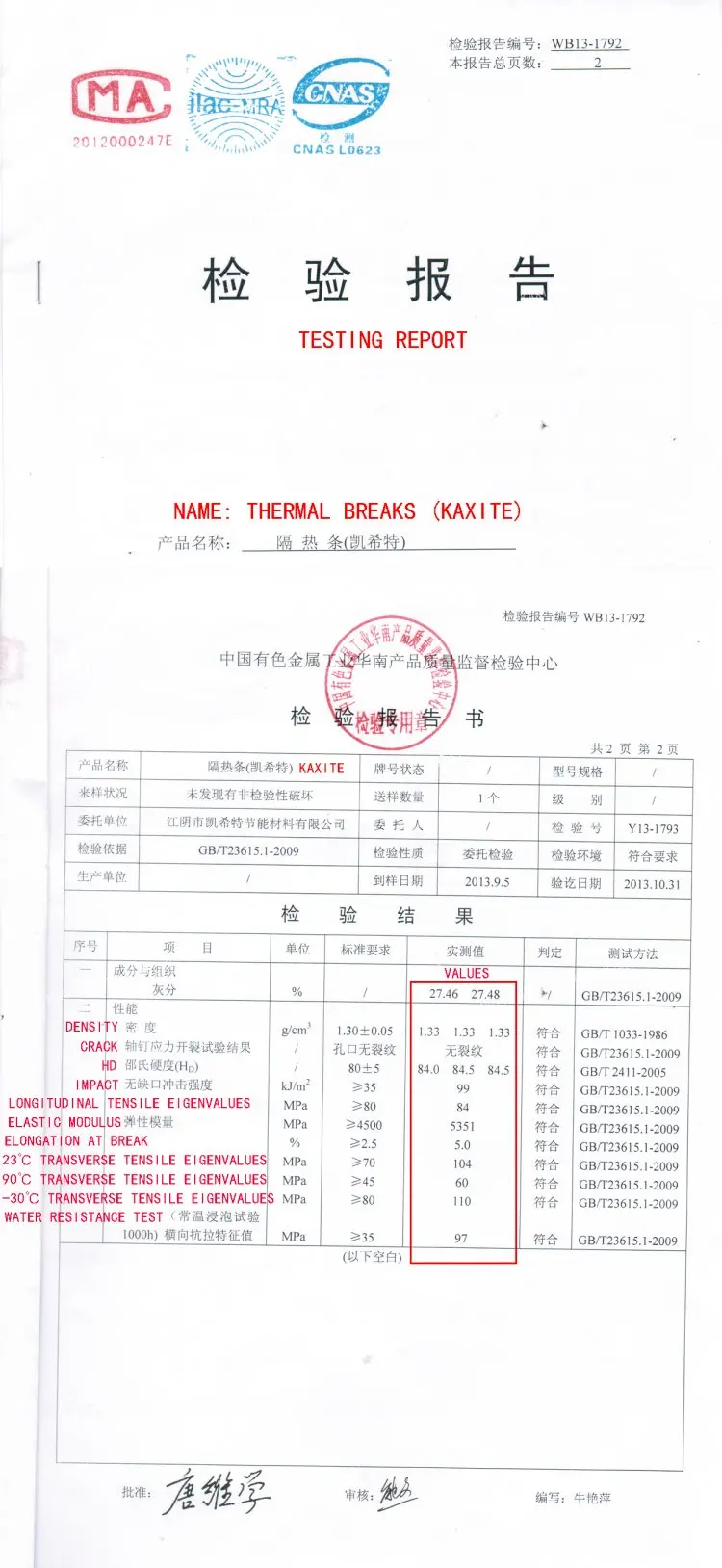

The performance of thermal barrier strips are in line with the Chinese standard GB/T 23615.1-2009 and the European Standard EN 14024:2004, for KAXITE series, the performance is rather higher than the standard value.

Details of related standard:

GB/T 23615.1-2017 Accessorial material for architectural aluminum alloy profiles -- Part 1: Thermal barrier strip of polyamide

EN 14024-2004 Metal profiles with thermal barrier -- Mechanical performance Requirement, proof and tests for assessment

YS/T 437-2008 Aluminium profiles moment of inertia calculation methods and computing software requirements

JG/T 174-2005 Thermal barrier strips for construction industry

GB 5237.6 -2012 Wrought aluminium alloy extruded profiles for architecture -- Part 6: Thermal barrier profiles

GB/T 8478-2008 Aluminium windows and doors

GB/T 8484-2008 Graduation and test for thermal insulating properties of doors and windows

JG 175-2011 Insulating aluminum alloy profiles with thermal barrier for buildings

UL94 Standard for Tests for Flammability of Plastic Materials for Parts in Devices and Appliances

ASTM E84 Standard Test Method for Surface Burning Characteristics of Building Materials

NFPA 285 Standard Fire Test Method for Evaluation of Fire Propagation Characteristics of Exterior Non-Load-Bearing Wall Assemblies Containing Combustible Components

In 2015, we became the leader of the Chinese National Standard Committee (for revising of GB/T 23615.1-2009) .

(KAXITE Series)(made of pure new raw material of PA66), you can see the extremely better performance of thermal break polyamide strips as shown below:

Raw Materials & Granulation:

We granuled by ourselves to ensure the quality of raw material for PA66GF25 thermal insulation strips.

What's the most important component in the raw material of Heat Insulation Profiles for windows & doors? Not Dupond, not extremely expensive fiberglass, it's Anti-aging agent and Antioxidants.

Think what will happen if there's no such anti-aging agents or antioxidants? Heat Insulation Profiles for windows & doors may age fastly by exposing to wind and sun,and maybe just for less than 10 years, the polymer profiles would break and glasses and windows will fall from such high curtain walls!! It's deadly! In addition, most completed raw materials in the market for thermal barriers manufacturers have no antioxidants which it must be added just beacause of its high cost. We have our own capacity of granulation to ensure that our raw materials contain these important elements to avoid this situation happening!

ISO9001:2021 Manutacturing

PACKING AND TRANSPORT

About Packing

Our particle packaging is packaged in a waterproof bag. Each time the vehicle is loaded, it will be spot-checked whether the weight of each package is qualified. Generally speaking, there will be pallets underneath to bear the weight, which is convenient for subsequent packing, and by the way, prevents damage to the packaging bag caused by violent transportation. The goods on each pallet will be wrapped with stretch film to reduce the intrusion of water mist during shipping.

About Transport

Our company generally chooses sea transportation for transportation, which is fast, safe and cost-effective in comparison. Of course, if the customer has special needs, we will also choose the corresponding air or rail transportation according to the customer's requirements.

OEM of Performance (Granulation)!

We support customizing any special performance polyamide resin for polyamide thermal break strips, even flame retardant required.

![fr test[1]](https://sc01.alicdn.com/kf/HTB1F97ImmYH8KJjSspdq6ARgVXah/223541288/HTB1F97ImmYH8KJjSspdq6ARgVXah.jpg)

OEM of Colors!

If you want different colors of PA66GF25, KAXITE can do for you.

Service Advantages:

1, Over 10.000 tons supply capacity per year.

2, KAXITE is familiar with the performance of final product thermal break, so the polyamide raw material produced here is quite friendly for extrusion;

3, MOQ is not existing here;

4, Customize is possible here, for performance/color/cost...

Packing:

25KG/Bag, or 1 Ton/Bag.

So far, our team has received customers from all over the world. Our professionalism and enthusiasm leave a deep impression on every customer.

KXT has applied for many patents, including but not limited to plastic particles, heat insulation strips, etc.

Welcome your inquiry and order.