PLA heat-resistant enhanced modified compostable degradable material

FULLY BIODEGRADABLE MATERIAL DEGRADABLE PLASTIC PARTICLES

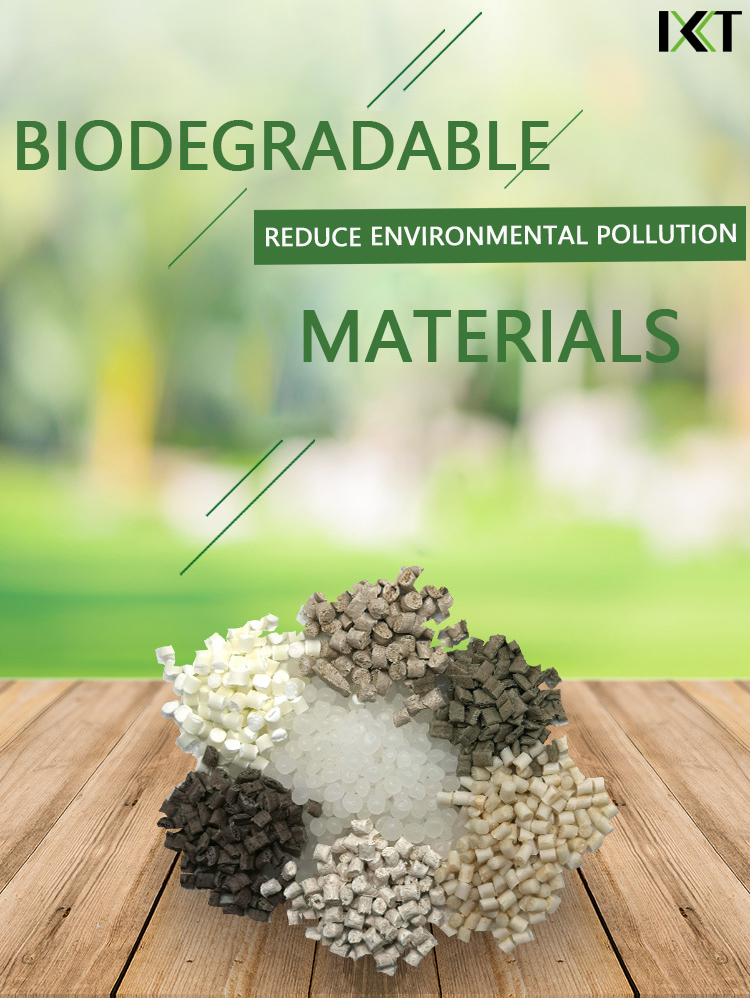

Degradable plastic particles are a kind of biodegradable material, which can reduce environmental pollution, which is an inevitable trend of social development in various countries.

What are degradable particles?

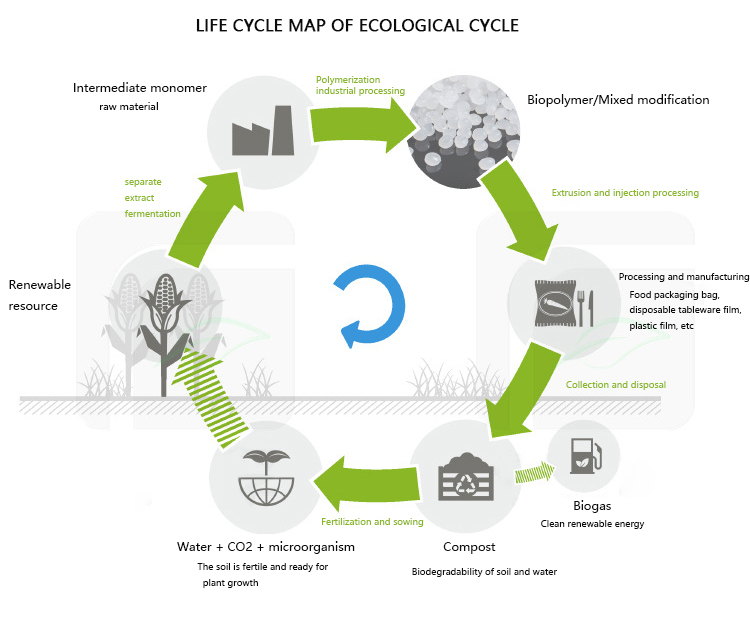

Under composting conditions, it can be completely degraded into carbon dioxide and water within 180 days. Natural conditions are related to temperature and humidity and can be completely degraded within 2-5 years. Achieve complete biodegradation.

product description

Comparison of fully degradable plastics and traditional plastics

100% compostable degradable. Compared with traditional petrochemical plastics per unit weight, it can reduce carbon dioxide emissions by more than 50%.

Does not contain PB, CD, HG, CR, PBB, PBDE and other harmful elements. Does not contain ortho-benzene plasticizer, bisphenol A and other harmful substances. The content of heavy metals complies with the ROHS directive.

The product is mainly a mixture of PLA (polylactic acid) and starch, and the obtained film product has excellent tensile properties.

Mainly suitable for blow molding process and film products. Typical products include supermarket shopping bags, various garbage bags, clothing packaging bags, industrial product packaging, etc.

The product has passed the EU EN 13432 and the US ASTM 6400, fully biodegradable standard certification, and passed the SGS certification.

Degradable granular raw materials

Types of raw materials

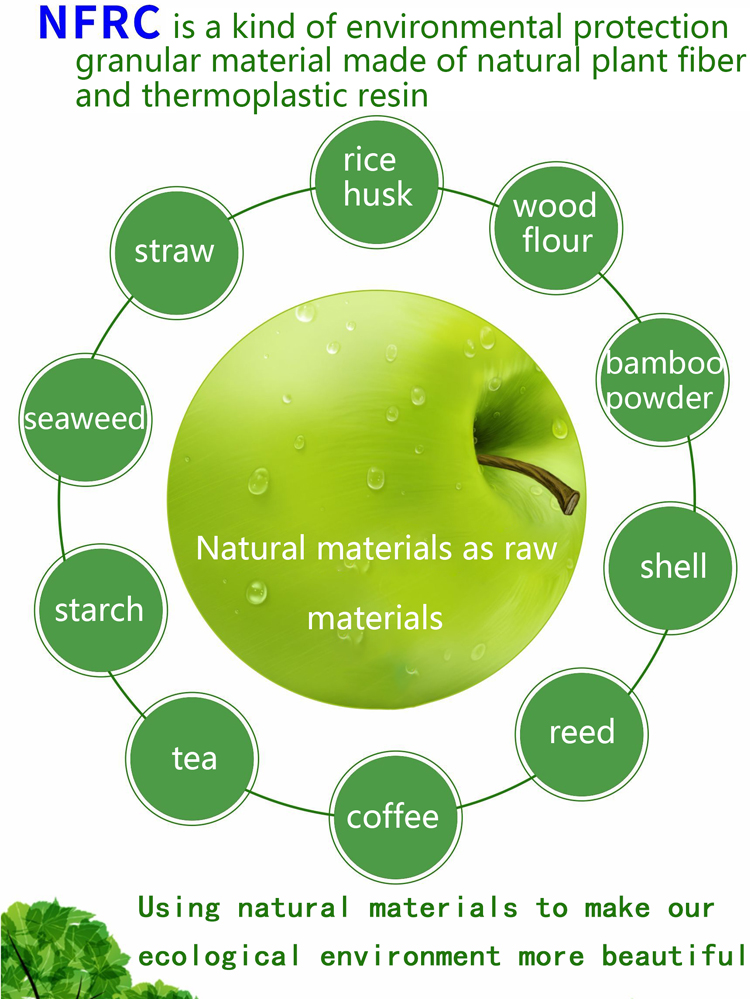

Bio-based plastics: Unlike traditional plastics, bio-based polymers are derived from renewable resources such as sugar, starch and vegetable oil fibers. Among them, corn, sugar cane and grains are the most common raw materials.

Petroleum-based plastics: the use of petrochemical resources to synthesize biodegradable plastics, mainly based on petrochemical products, through chemical synthesis, is a polymer PCL, PBS, PVA, PBAT, etc.

Compostable degradation: Under composting conditions, due to the biological reaction process, plastics can be degraded and decomposed, and finally decomposed into carbon dioxide and water, mineralized inorganic salts and new biomass, and will not pollute the soil.

Application field

Application of degradable plastics in life

Injection molding

Extrusion processing

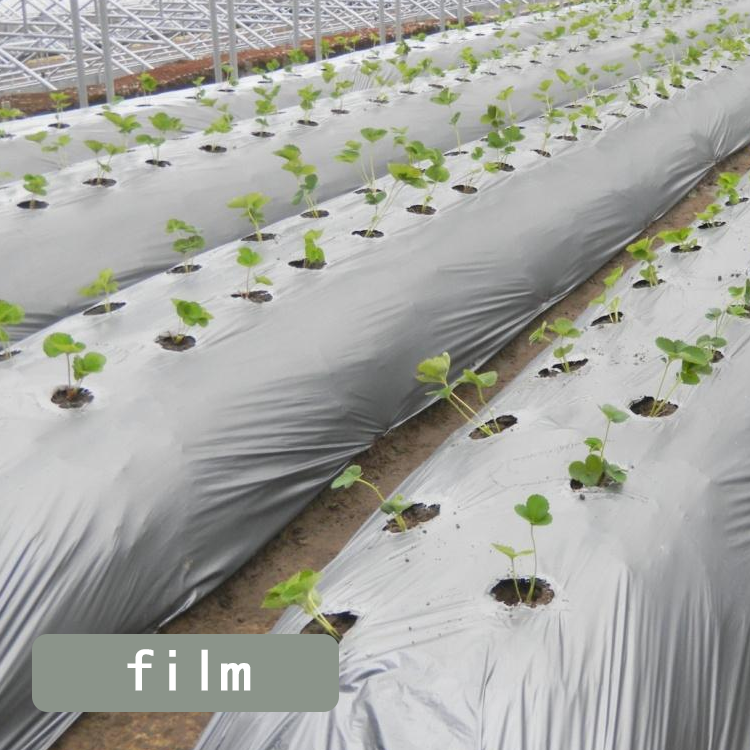

Film processing

Approach

Various treatment methods for degrading plastics.

compost

Under the conditions of compost degradation, the product can be 100% biodegraded within 180 days, and the final product of degradation is carbon dioxide and water. The composting conditions are as follows: temperature is 58±2°C, humidity is 98%, and there are certain microorganisms.

Landfill disposal

Landfill conditions are different from composting conditions, so the product degradation rate is slower, usually 2-5 years, but the degradation products will not pollute the groundwater, will not harm the growth of plants, and will not waste arable land.

incineration

The calorific value of degradable plastic products is very small. The products of complete combustion are carbon dioxide and water, which will not pollute the air.

From nature back to nature

Traditional petroleum-based plastics have caused serious white pollution to the earth, while biodegradable plastics mainly use renewable plant resources, such as corn, cassava and sucrose. They can replace most synthetic plastics and reduce human dependence on petroleum resources. .

Sincere cooperation, only for supply

KXT wholeheartedly provides every customer with the best quality service.

Support sample

Combining the actual situation to reduce the cost of new product samples, the company supports providing samples as appropriate. After providing project information and purchase quantity, our company will provide free samples after verification until the product is officially produced.

Material recommendation

According to product performance, application scenarios and molding equipment, we provide effective and operable solutions, such as injection molding, extrusion, blow molding and other material selection recommendations and construction recommendations.

Material customization

Our company will determine physical properties according to customer needs, and tailor materials to meet product requirements according to customer needs.

Welcome your inquiry.