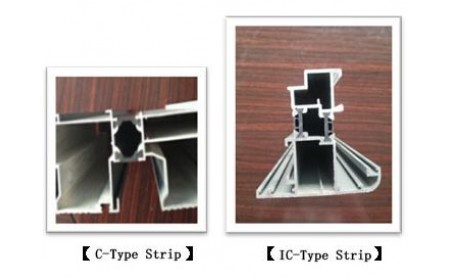

the comparison test between the C type thermal insulation strip and the IC one

The summary report of the comparison about the performance test of IC type thermal insulation strip and C type thermal insulation strip

The summary report of the comparison about the performance test of IC type thermal insulation strip and C type thermal insulation strip

1 Background of the project

With the development of thermal insulation profiles and market demand, new functions have been continuously proposed for thermal insulation strips, so some non-I-type thermal insulation strips have emerged. The C-shaped strip is one of them, which improves the waterproof, dustproof and aesthetic functions of the I-type thermal insulation strip under the premise of having heat insulation performance. Although the C-type bar has added some other functions, due to its structural defects, the C-type bar has greatly reduced lateral tensile properties, which limits the application range of the C-type bar. In order to solve the problem of low transverse tensile strength of C-shaped strips, Jiangyin Liangyou has developed IC-type thermal insulation strips that are water-proof, dust-proof, and aesthetically pleasing. They also guarantee horizontal tensile strength and are special-shaped thermal insulation. Development direction. This test project is to verify the advantages of IC strips and C strips in the transverse tensile properties.

2 test purpose

2.1 Through the test to understand whether the lateral tensile properties of IC thermal insulation strip is better than one of C-type thermal insulation strip.

2.2 Through the test results to understand whether the horizontal tensile properties of IC thermal insulation strip meet the requirement of GB/T 23615.1-2009.

3 test

3.1 Sample source

IC-type heat insulation strips are provided by domestic companies those produce heat insulation strip .

The C-type heat insulation strip is an excellent quality C-shape strip among 8 heat-insulation-strip companies.

3.2 Test participants unit

standard of amendation centers and test sites

3.3 Test Equipment

Electronic universal material testing machine with high temperature

3.4 Test items

Perform horizontal, high-temperature, and low-temperature horizontal tensile tests on IC and C-insulated bars

3.5 Test process

Sampling according to GB/T 23615.1-2009 standard and horizontal and high temperature horizontal tensile strength test.

4 test result

4.1 Table 1 lists the tensile strength at room temperature of IC strips and C strips tested by seven participating units.

|

|

1#test unit |

2#Test unit |

3#Test unit |

4#Test unit |

5#Test unit |

6#Test unit |

7#Test unit |

average |

|

IC strips |

82 |

69 |

93 |

82 |

78 |

85 |

76 |

81 |

|

C strip |

27 |

28 |

29 |

30 |

30 |

33 |

21 |

28 |

|

different rate% |

204 |

146 |

224 |

174 |

156 |

157 |

272 |

190 |

Table 1 Comparison of Tensile Strength at Room Temperature Between IC and C

Test Environment: 23°C 50%RH Test Condition: Drying at 140°C 6H, transverse stretching in room temperature.

4.2 Table 2 lists the high temperature horizontal tensile strengths of IC strips and C strips tested by 7 test units.

Table II Comparison of high-temperature transverse tensile strength of IC strips and C strips

Test conditions: 90 °C Test conditions: 140 °C 6H drying, transverse stretching at room temperature

|

|

1#test unit |

1#test unit |

1#test unit |

1#test unit |

1#test unit |

1#test unit |

1#test unit |

average |

|

|

IC strip |

46 |

45 |

51 |

45 |

46 |

45 |

37 |

45 |

|

|

C strip |

23 |

20 |

21 |

24 |

22 |

22. |

13 |

21 |

|

|

Different rate% |

100 |

125 |

142 |

89 |

111 |

102 |

174 |

120 |

|

4.3 Table 3 lists the low temperature transverse tensile strengths of IC strips and C strips tested by 7 test units

Table III Comparison of Low-Temperature Tensile Strength of IC Strips and C Strips

Test temperature: -30°C Test conditions: Drying at 140°C6H, transverse stretching at room temperature

|

|

1#test unit |

2#test unit |

3#test unit |

4#test unit |

5#test unit |

6#test unit |

7#test unit |

average |

|

IC strip |

75 |

75 |

73 |

80 |

65 |

82 |

65 |

74 |

|

C strip |

15 |

15 |

21 |

14 |

13 |

22 |

11 |

16 |

|

Different rate% |

400 |

400 |

247 |

457 |

415 |

279 |

514 |

387 |

5 Test conclusions

5.1 From the test results, it can be seen that the transverse tensile strength of the IC type thermal insulation strip is better than that of the C type thermal insulation strip.

5.2 Table 1 shows that the horizontal tensile strength data of 6 tested ICs at room temperature meet the requirements of GB/T 23615.1-2009, 1 data is slightly lower than that of GB/T 23615.1-2009, and C indicates tensile strength at room temperature. Neither meet the requirements of GB/T23615.1-2009.

5.3 Table 2 shows that the high temperature horizontal tensile strength data of 6 IC strips tests meet the requirements of GB/T 23615.1-2009, 1 data is lower than the requirements of GB/T 23615.1-2009, and all the data of C type high temperature horizontal tensile strength does not meet the requirements of GB/T23615.1-2009.

5.4 Table 3 shows that the low temperature horizontal tensile strength data of IC strips test meets the requirements of GB/T23615.1-2009, the five data are lower than the requirements of GB/T23615.1-2009, and all data of the C low temperature tensile strength does not meet the requirements of GB/T23615.1-2009.

5.5 The average tensile strength at room temperature of IC strip at room temperature is 1.9 times higher than the tensile strength at room temperature in the transverse direction of C. The average high temperature tensile strength of IC strip is 1.2 times higher than the tensile strength at high temperature of strip C at an average, and the average tensile strength at low temperature of IC strip is C low temperature tensile strength of 3.9 times.

5.6 The development of special-shape heat insulation strips can meet the requirements of new functions and meet the mechanical properties specified in GB/T23615.1-2009.